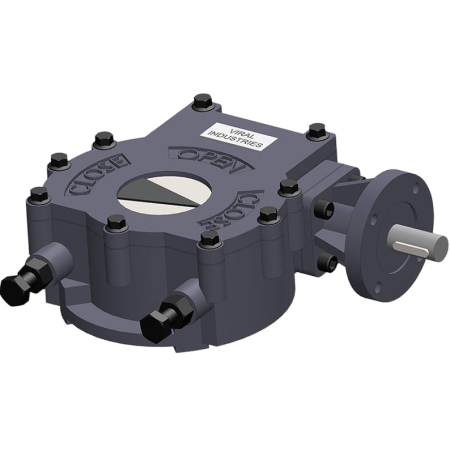

Quarter Turn Gearbox Manufacturer

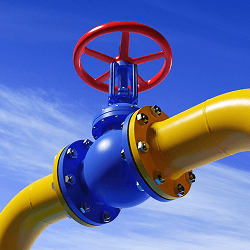

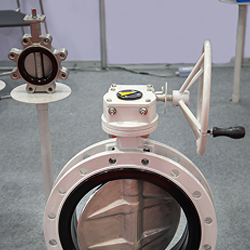

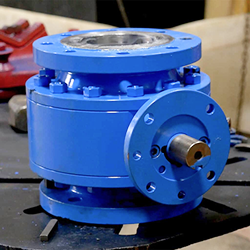

Viral Industries is a renowned Quarter-Turn Worm Gearbox manufacturer, supplier & exporter in the USA, Europe, Canada, and Gulf. A Quarter-Turn Worm Gearbox is a mechanical device that transmits rotational power from one shaft to another at a 90-degree angle. It is typically used when precise and controlled torque is required, such as in valve actuation systems or other rotary motion control applications.

A Quarter-Turn Worm Gearbox manufacturer – Viral industries is a company that specializes in the design and production of Quarter-Turn worm gearboxes. We ensure high quality and reliable performance for our customers. Furthermore, our Quarter-Turn Worm Gearbox can deliver torque ranging between 800 Nm – 500000 Nm (590 lbf-ft – 3,68,800 lbf-ft).

Note: Our manufacturing unit is only in India, but we export Quarter-Turn Worm Gearbox to the USA, Europe, Canada, and the Gulf.

Models of Quarter Turn Gearbox

Our quarter-turn worm gearbox models, VW, VWE, VWSGA, and VWESGA, deliver reliable torque from 800 Nm to 500,000 Nm for manual or automated valve control. Built with IP65–IP68 protection, ISO 5211 compatibility, and rugged design for oil, gas, water & chemical industries.

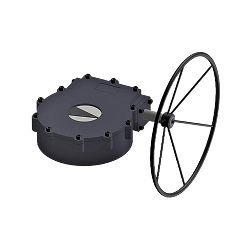

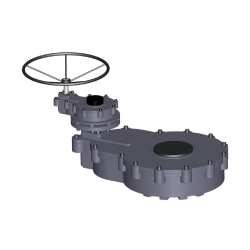

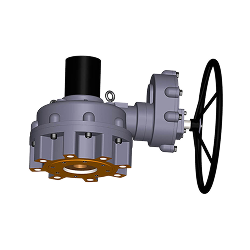

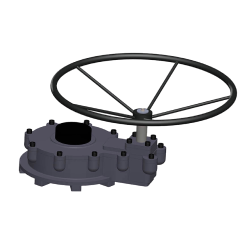

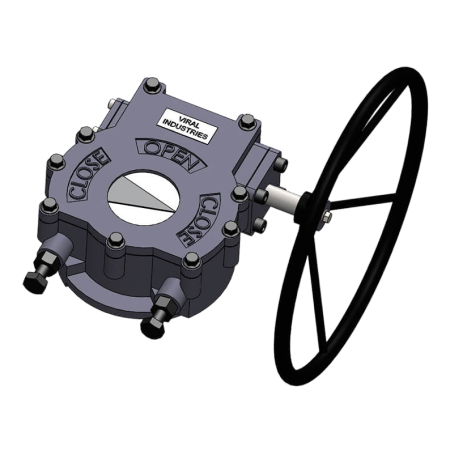

Quarter Turn Worm Gearbox - Hand-Wheel Operation

Designed for effortless manual control of ball, butterfly & plug valves, our VW series delivers high torque (800–4,500 Nm) with minimal hand-wheel effort. Ideal for remote sites or backup systems, built rugged for oil, gas, water & chemical industries.

Get a Quote

| Viral Ind. Model No. | Output torque capacity | Ratio | M A (±10%) | Hand-wheel Diameter | Hand-wheel Effort | |||

|---|---|---|---|---|---|---|---|---|

| Nm. | lbf-ft | mm | inch | lbs | kilogram | |||

| VW-07 | 800 | 590 | 40 | 14 | 250 | 10 | 102.8 | 46.6 |

| VW-10 | 1,100 | 811 | 42 | 15 | 400 | 16 | 82.5 | 37.4 |

| VW-15 | 1,800 | 1,327 | 42 | 16 | 400 | 16 | 126.5 | 57.4 |

| VW-20 | 2,400 | 1,770 | 52 | 20 | 500 | 20 | 108.0 | 49.0 |

| VW-30 | 3,700 | 2,729 | 52 | 20 | 600 | 24 | 138.7 | 62.9 |

| VW-40 | 4,500 | 3,320 | 55 | 21 | 600 | 24 | 160.7 | 72.9 |

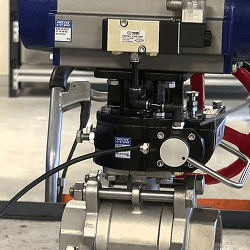

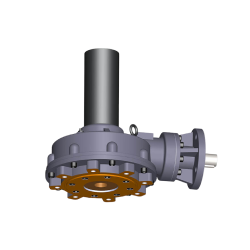

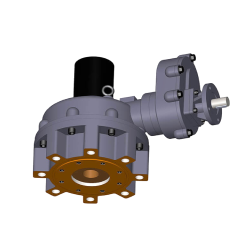

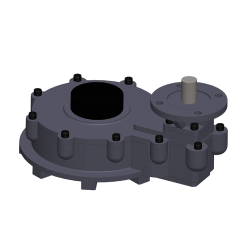

Quarter Turn Worm Gearbox - Actuator Operation

Perfectly engineered for automated valve control, our VWE series delivers high torque (800–4,500 Nm) with precise input matching, ideal for electric, pneumatic, or hydraulic actuators in oil, gas & chemical plants. ISO 5211 flanges ensure seamless integration.

Get a Quote

| Viral Ind. Model No. | Output torque capacity | Ratio | M A (±10%) | Input torque capacity | Mounting Flange at Actuator Side (ISO 5211) | ||

|---|---|---|---|---|---|---|---|

| Nm. | lbf-ft | Nm. | lbf-ft | ||||

| VWE-07 | 800 | 590 | 40 | 14 | 57 | 42 | F10, F14 |

| VWE-10 | 1,100 | 811 | 42 | 15 | 73 | 54 | F10, F14 |

| VWE-15 | 1,800 | 1,327 | 42 | 16 | 112 | 83 | F10, F14 |

| VWE-20 | 2,400 | 1,770 | 52 | 20 | 120 | 88.5 | F10, F14 |

| VWE-30 | 3,700 | 2,729 | 52 | 20 | 185 | 137 | F10, F14 |

| VWE-40 | 4,500 | 3,320 | 55 | 21 | 214 | 158 | F10, F14, F16 |

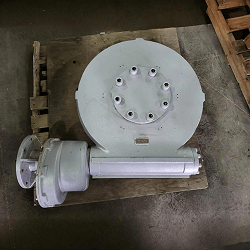

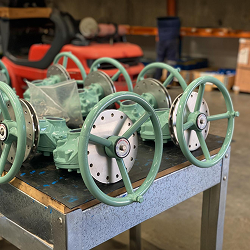

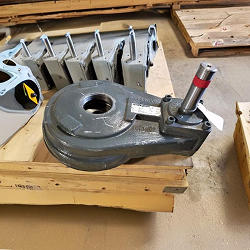

Quarter Turn Worm Gearbox with Spur Gearbox - Hand-Wheel Operation

Built for heavy-duty manual control, our VWSGA series delivers massive torque (4,500–500,000 Nm) with surprisingly low hand-wheel effort, ideal for large ball/butterfly valves in oil, gas & power plants where reliability and ease of operation matter most.

Get a Quote

| Viral Ind. Model No. | Output torque capacity | Ratio | M A (±10%) | Hand-wheel Diameter | Hand-wheel Effort | |||

|---|---|---|---|---|---|---|---|---|

| Nm. | lbf-ft | mm | inch | lbs | kilogram | |||

| VWSGA-40 | 4,500 | 3,320 | 165 | 54 | 600 | 24 | 62.4 | 28.3 |

| VWSGA-60 | 6,000 | 4,425 | 194 | 62 | 600 | 24 | 72.6 | 32.9 |

| VWSGA-80 | 8,000 | 5,900 | 220 | 70 | 600 | 24 | 85.7 | 38.9 |

| VWSGA-100 | 10,000 | 7,375 | 300 | 95 | 600 | 24 | 78.9 | 35.8 |

| VWSGA-150 | 15,000 | 11,063 | 449 | 143 | 700 | 28 | 67.4 | 30.6 |

| VWSGA-250 | 25,000 | 18,440 | 605 | 190 | 700 | 28 | 84.6 | 38.4 |

| VWSGA-350 | 35,000 | 25,815 | 992 | 320 | 700 | 28 | 70.3 | 31.9 |

| VWSGA-500 | 50,000 | 36,878 | 1039 | 340 | 700 | 28 | 94.5 | 42.9 |

| VWSGA-750 | 75,000 | 55,317 | 1425 | 461 | 750 | 30 | 97.6 | 44.3 |

| VWSGA-1000 | 1,00,000 | 73,756 | 1768 | 569 | 1000 | 40 | 79.1 | 35.9 |

| VWSGA-1500 | 1,50,000 | 1,10,635 | 2109 | 655 | 1000 | 40 | 106.3 | 48.2 |

| VWSGA-2000 | 2,00,000 | 1,47,512 | 2381 | 762 | 1000 | 40 | 118.1 | 53.6 |

| VWSGA-2500 | 2,50,000 | 1,84,390 | 2510 | 800 | 1000 | 40 | 140.6 | 63.8 |

| VWSGA-3750 | 3,75,000 | 2,76,585 | 3332 | 1051 | 1000 | 40 | 160.5 | 72.8 |

| VWSGA-5000 | 5,00,000 | 3,68,800 | 3808 | 1208 | 1000 | 40 | 186.2 | 84.5 |

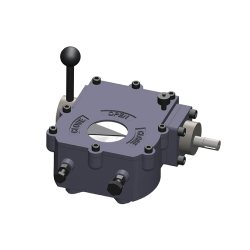

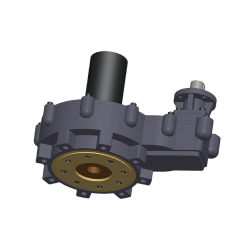

Quarter Turn Worm Gearbox with Spur Gearbox - Actuator Operation

Engineered for high-torque automated systems, our VWESGA series delivers massive output (4,500–500,000 Nm) with precise input matching, ideal for electric/pneumatic actuators in oil, gas & power plants. ISO 5211 flanges ensure seamless, reliable integration.

Get a Quote

| Viral Ind. Model No. | Output torque capacity | Ratio | M A (±10%) | Input torque capacity | Mounting Flange at Actuator Side (ISO 5211) | ||

|---|---|---|---|---|---|---|---|

| Nm. | lbf-ft | Nm. | lbf-ft | ||||

| VWESGA-40 | 4,500 | 3,320 | 165 | 54 | 83 | 61 | F10,F14 |

| VWESGA-60 | 6,000 | 4,425 | 194 | 62 | 97 | 71 | F10, F14 |

| VWESGA-80 | 8,000 | 5,900 | 220 | 70 | 114 | 84 | F10, F14 |

| VWESGA-100 | 10,000 | 7,375 | 300 | 95 | 105 | 78 | F10,F14 |

| VWESGA-150 | 15,000 | 11,063 | 449 | 143 | 105 | 77 | F10, F14 |

| VWESGA-250 | 25,000 | 18,440 | 605 | 190 | 132 | 97 | F10, F14 |

| VWESGA-350 | 35,000 | 25,815 | 992 | 320 | 109 | 81 | F10, F14 |

| VWESGA-500 | 50,000 | 36,878 | 1039 | 340 | 147 | 108.5 | F10, F14 |

| VWESGA-750 | 75,000 | 55,317 | 1425 | 461 | 163 | 120 | F10, F14 |

| VWESGA-1000 | 100,000 | 73,756 | 1768 | 569 | 176 | 130 | F10,F14, F16 |

| VWESGA-1500 | 1,50,000 | 1,10,635 | 2109 | 655 | 236 | 174 | F10, F14, F16 |

| VWESGA-2000 | 2,00,000 | 1,47,512 | 2381 | 762 | 262.5 | 194 | F10, F14, F16 |

| VWESGA-2500 | 2,50,000 | 1,84,390 | 2510 | 800 | 312.5 | 230.5 | F10, F14, F16 |

| VWESGA-3750 | 3,75,000 | 2,76,585 | 3332 | 1051 | 357 | 263 | F10, F14, F16 |

| VWESGA-5000 | 5,00,000 | 3,68,800 | 3808 | 1208 | 414 | 305 | F10,F14, F16 |

Valve Mounting Detail

Ensure perfect fit every time, our gearboxes feature ISO 5211-compliant flanges (F07 to F60) and support spindle diameters from 35mm to 350mm, designed for seamless integration with ball, butterfly & plug valves across global industrial applications.

| Viral Ind. Model No. | Valve Side Mounting Flange (ISO 5211) | Max. Spindle Diameter (mm) |

|---|---|---|

| VW-07 / VWE-07 | F10, F07 | 35 |

| VW-10 / VWE-10 | F12, F10 | 45 |

| VW-15 / VWE-15 | F14, F12 | 50 |

| VW-20 / VWE-20 | F16, F14, F12 | 55 |

| VW-30 / VWE-30 | F14, F16 | 60 |

| VW-40 / VWE-40 | F16, F25 | 70 |

| VWSGA-40 / VWESGA-40 | F16, F25 | 70 |

| VWSGA-60 / VWESGA-60 | F16, F25 | 80 |

| VWSGA-100 / VWESGA-100 | F16, F25, F30 | 85 |

| VWSGA-150 / VWESGA-150 | F30, F35 | 100 |

| VWSGA-250 / VWESGA-250 | F30, F35, F40 | 110 |

| VWSGA-350 / VWESGA-350 | F35, F40 | 120 |

| VWSGA-500 / VWESGA-500 | F35, F40 | 155 |

| VWSGA-750 / VWESGA-750 | F35, F40, F48 | 185 |

| VWSGA-1000 / VWESGA-1000 | F40, F48 | 185 |

| VWSGA-1500 / VWESGA-1500 | F48, F60 | 230 |

| VWSGA-2000 / VWESGA-2000 | F48, F60 | 270 |

| VWSGA-2500 / VWESGA-2500 | F48, F60 | 300 |

| VWSGA-3750 / VWESGA-3750 | F48, F60 | 300 |

| VWSGA-5000 / VWESGA-5000 | F48, F60 | 350 |

Features:

- Clockwise rotation of input will give clockwise rotation of output.

- Self-Locking gearbox.

- Bearings supported assembly.

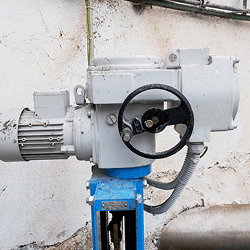

- Suitable for Actuator operation.

- Grease Lubricant Gearbox.

- Higher ratio options to reduce effort.

- Locking Arrangement.

- Available for marine application.

- Available for horizontal hand-wheel orientation

Bore Options for Worm-Wheel Quadrant:

- Round Shape with multiple key-way

- Square Shape

- Hexagon Shape

Temperature Limit:

- Normal application -20˚C To 120˚C

- High temperature application up to 150˚C

- Low temperature application up to -50˚C

Material Options for Worm-Wheel:

- Phosphorus Bronze (PB-2)

Enclosure:

- IP-65 ,IP-67, IP-68

Why Choose Us?

At Viral Industries, we are driven by innovation, integrity, and engineering excellence. Our expertise in valve gearbox manufacturing allows us to deliver reliable solutions that adapt to your industry’s toughest challenges - ensuring performance, precision, and long-term trust.

-

Flexibility

We understand that every industry has unique requirements. That’s why our manufacturing process is designed for customization and adaptability - ensuring that every gearbox we produce meets your exact operational needs.

-

Quality

Quality is at the core of everything we do. From raw material selection to final inspection, we follow stringent quality standards to deliver gearboxes that perform flawlessly, even under the most demanding conditions.

-

Sustainability

We are committed to sustainable manufacturing practices that minimize waste and energy consumption. Our goal is to build products that not only perform efficiently but also contribute to a greener industrial future.

-

Transparency

Honesty and clarity define our partnerships. We maintain open communication throughout every project - from design to delivery - ensuring you always know what to expect, with no hidden surprises.

Plant Address:

international inquiry:

domestic inquiry:

Email address:

get in touch

Custom Gearbox Solutions. Trusted Worldwide

As a leading valve gearbox manufacturer, we deliver high-performance, custom gearbox solutions for global industrial applications. We design and build durable valve gearboxes that ensure smooth, reliable operation in challenging industrial environments across the globe.

-

100+

Satisficed Clients

-

21000sq. ft.

area of manufacturing unit

-

300Nm to 250000Nm

We manufacture sizes of gearbox

We export in20+Countries

Our Clients

Get the Answers You Need to Move Forward.

Get clear, concise answers to the most common questions about valve gearboxes. Make informed decisions with expert insights and practical guidance.

A quarter-turn worm gearbox rotates a valve (like ball, butterfly, or plug types) by 90° to open or close flow. It’s widely used in oil & gas, power, water treatment, and chemical plants for reliable, high-torque manual or automated valve control.

Our gearboxes deliver output torque from 800 Nm up to 500,000 Nm (590–368,800 lbf-ft), with models like VW (manual), VWE (actuator), VWSGA, and VWESGA to suit light-duty or extreme industrial applications.

Yes. All models come with IP65, IP67, or IP68-rated enclosures, offering full protection against dust, water immersion, and corrosion, ideal for offshore, marine, desert, or chemical exposure conditions.

Yes. Models like VWSGA and VWESGA support dual-mode operation, allowing seamless transition from automated actuator control to manual hand-wheel during emergencies or maintenance, ensuring process continuity and safety.

Absolutely. We follow ISO 5211 standards for both valve-side and actuator-side flanges (F07 to F60) and support multiple spindle bore shapes, round (with keyways), square, or hexagon, for easy integration with existing systems worldwide.